The world of industrial automation is changing fast, and air cylinders are still at the heart of many routine jobs, from car production to packaging lines. New technologies keep popping up, and companies are now looking for gear that is smarter, greener, and easier to customize than ever before. For procurement teams that buy through an automation parts supplier, keeping an eye on these shifts is no longer optional if they want to stay ahead of competitors and make sure new parts play nicely with existing systems.

This post digs into the major currents expected to shape air-cylinder production and use by 2025. The goal is to give purchasing managers, engineers, and plant managers a clear snapshot they can act on.

Increasing Demand for Smart and Connected Air Cylinders

A big story right now is how quickly sensors and wireless links are landing in everyday air cylinders. Thanks to the push known as Industry 4.0, manufacturers are bolting on gear that tracks piston position, stroke speed, and even temperature as each cycle happens.

The Lift from Smart Features

Smart air cylinders pack a tiny microchip, and that chip brings a mountain of handy perks.

- Predictive Maintenance watches for signs of wear before a big crash, which means fewer surprise breakdowns and a longer life for expensive gear.

- Real-time feedback makes Enhanced Process Control possible-factory operators can tweak settings on the fly and shave minutes off every cycle.

- With Remote Monitoring, a single technician can check on machines spread across three states, turning one desk into a headquarters.

An Edge That Matters

Suppliers who shelf these hi-tech cylinders suddenly look a lot more appealing to manufacturers chasing after connected assembly lines. The trend is clear: as factories pile on sensors and data clouds, the demand for intelligent parts is bound to spike.

Greener Tomorrow

Sustainability isn’t just boardroom buzz anymore; it flows through invoices, shipping lists, and even factory floor chatter. Air-cylinder makers are flipping their playbooks to trim waste and keep the planet in mind.

What Green Looks Like

- Some shops are swapping brand-new aluminum for recycled stock or even tossing in biodegradable polymers, shrinking the need for raw materials.

- Cutting-edge ovens and robotic welders shave kilowatts off every run, so Energy-Efficient Production stays under the energy radar.

- Engineers now sketch Circular Economy Models-cylinders that unscrew, get a fresh seal, and start another tour instead of winding up in a landfill.

Working with an automation parts supplier can be about more than just speed and price. When a company picks partners who openly commit to greener practices, it checks off the look-good box in public relations and quietly dodges new environmental fines popping up around the globe.

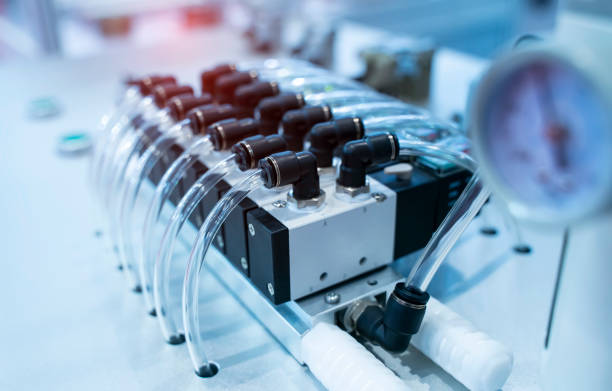

Customization and Modular Designs for Diverse Applications

Factories rarely do the same task from one month to the next, so demand for one-off automation gear keeps climbing. A growing number of air cylinder manufacturers answer calls with plug-and-play platforms that let engineers choose everything from stroke length to cushion type in a single click.

That plug-and-play logic offers real, day-to-day benefits:

- Rapid Prototyping and Deployment: Builders can snap a custom setup together in hours instead of weeks.

- Reduced Inventory Costs: Distributors keep a few core modules on the shelf, not dozens of niche cylinders.

- Simplified Maintenance: Swapping one standard part saves time, headaches, and nearly all the downtime.

Teaming up with an automation-parts supplier that has a beefy modular catalog and responsive engineers gives plants the freedom to pivot when orders change-yesterday-without losing sleep over quality or delays.

Advanced Materials Boosting Cylinder Performance

Material science never sits still, and that constant churn keeps air cylinders one step ahead of punishment. From rugged new alloys to clever surface treatments, manufacturers are squeezing every last drop of toughness out of every part.

Take a look at a few game-changers showing up on shop floors:

- Corrosion-Resistant Coatings protect tubes from caustic spills and salty air, doubling service life with barely a scratch.

- Lightweight High-Strength Metals shave pounds off actuators yet push them to even faster cycles, trimming power bills in the bargain.

- Extreme-Temperature Components shrug off both searing heat and bitter cold, opening doors to applications once thought impossible.

Buyers who keep these upgrades in mind when chatting with automation parts suppliers specify cylinders that just keep working, season after season.

Supply Chains, Local Solutions

The last few years proved that long-distance haul routes are only as strong as the weather forecast-and sometimes the weather wins. Many air-cylinder makers have responded by planting factories and stocking centers closer to their customers, stitching up a tougher network.

Shifting production down the road offers several clear benefits:

- Quicker Shipments mean fewer sleepless nights wondering where the next shipment wound up, because freight hops a matter of hours instead of weeks.

- Easier compliance with import tariffs and regional codes lets purchasing agents skip figure-out-the-paperwork mode and get back to engineering.

- Cost Savings: When companies move manufacturing closer to home, they cut freight bills and dodge some of those pesky tariffs. The result is a price tag that feels a lot friendlier to customers.

- Cleaner Planet: Shorter hauls mean trucks and ships burn less fuel, so the supply chain shrinks both in miles and in carbon footprints.

Firms that rely on fast-moving automation parts cannot afford delays; one jammed delivery can throw off the whole assembly line. Choosing suppliers with warehouses or factories nearby creates a cushion against those risks and lets manufacturers pivot more freely.

Conclusion

By 2025, air cylinder makers will be leaning hard on smart tech, greener material choices, and custom designs. Anyone buying from an automation parts distributor needs to watch these shifts closely if they want their pneumatic gear to stay relevant.

Staying in sync with global trends helps factories run smoother, trims downtime, and keeps them one step ahead of rivals in a fast-changing market.

As air cylinders pick up intelligence, trim emissions, and mold themselves to unusual tasks, teamwork among builders, shippers, and end-users will drive the next leap in factory automation.