In today’s competitive electronics industry, scaling production without compromising quality is a top priority for manufacturers. Two vital pillars supporting this scalability are Surface Mount Technology (SMT) and high volume PCB assembly. By mastering these technologies, businesses can achieve faster turnaround times, consistent quality, and cost-effective production for both consumer electronics and industrial applications.

What is SMT and Why It Matters

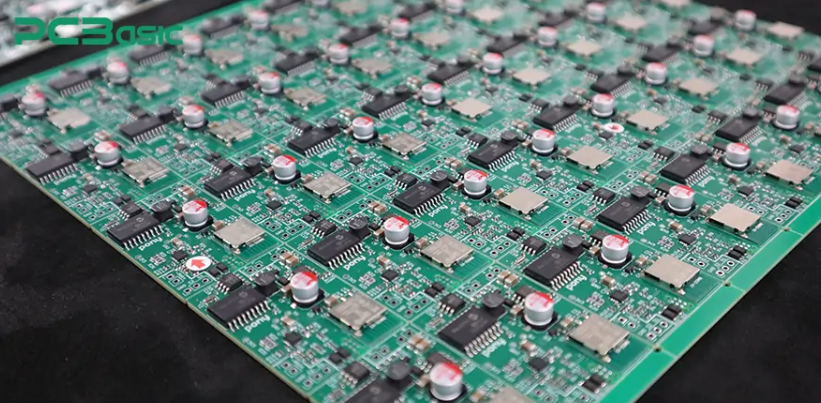

Surface Mount Technology (SMT) refers to the process of mounting electronic components directly onto the surface of a printed circuit board (PCB). Unlike traditional through-hole technology, SMT does not require drilling, enabling a more compact and automated assembly process.

Key benefits of SMT include:

- Miniaturization: Enables dense placement of components, supporting smaller and lighter devices.

- Automation Compatibility: Ideal for high-speed pick-and-place machines, enhancing productivity.

- Reliability: Fewer mechanical stresses and shorter interconnections improve signal integrity.

The Power of High Volume PCB Assembly

High volume PCB assembly refers to the production of large quantities of PCBs, typically for mass-market products like smartphones, wearables, and automotive electronics. This method requires precise process control, supply chain coordination, and advanced manufacturing systems.

Advantages of high-volume PCB assembly:

- Lower Cost per Unit: Economies of scale reduce manufacturing costs significantly.

- Faster Lead Times: Streamlined operations ensure rapid order fulfillment.

- Consistent Quality: Automation and rigorous quality checks ensure defect-free production.

How SMT and High Volume Assembly Work Together

When combined, SMT and high-volume assembly create a robust manufacturing ecosystem. SMT supports the rapid placement of tiny components, while high-volume lines manage throughput and consistency. Together, they enable:

- High-speed automated production

- Advanced quality control using AOI, X-ray, and functional testing

- Scalability from prototype to mass production

Choosing the Right Manufacturing Partner

Success in scalable electronics manufacturing depends heavily on your choice of EMS partner. Look for a manufacturer with:

- Multiple SMT lines and advanced equipment

- Proven experience in handling high-volume orders

- IPC and ISO certifications

- Full-process capabilities from component sourcing to final testing

Conclusion

Mastering SMT and high volume PCB assembly is essential for businesses looking to stay competitive in the fast-evolving electronics industry. By leveraging these technologies, companies can not only scale up efficiently but also maintain the high standards that today’s market demands.