The automation of industrial processes as well as the processes themselves need to be optimized requires effective thermal management for any equipment due to the need for dependability and due to reliability demands . Specifically, one of the technologies that is aiding offset these challenges is the EC fan (electronically commutated fan), which is now more commonly used over AC fans in industrial plants because of its smart controls, better efficiency, and increased savings over time.

For industrial cooling, EC fans are adopted at an accelerated pace and for further understanding, we will review the integration of EC fans with filter systems as well as examine how their proper implementation can optimize thermal control, minimize energy costs, cut down operating expenses, decrease overall equipment depreciation, enhance reliability, and save space while extending equipment lifespan.

EC vs AC Fan: A Technical and Functional Comparison

Both EC and AC fans differ in their power management architecture. AC fans have fixed speed operation due to reliance on alternating current while EC fans are powered by brushless DC motors with embedded electronics granting the benefits of precision, variable speed, efficiency, and performance.

The important advantages of EC fans when compared to AC fans include:

Partial load scenarios have up to 50% lower energy expenditure.

Built-in speed regulation via 0–10V or PWM signal input.

Less noise and more compact size.

Extended operational life due to lower friction from brushless motor operation.

Lower heat generation in comparison to AC fans.

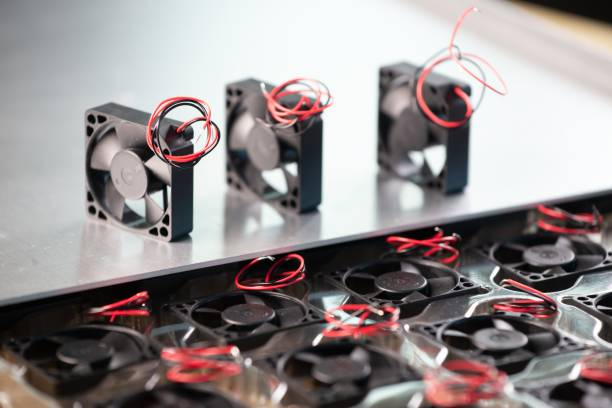

In industrial enclosures, use of an EC fan and a fan with filter will keep the critical electronic components internal to the enclosure and the environment clean, cool, and safe. The filter captures help to reduce the rate of dust particulates while EC technology controlled fans dynamically adjust to the thermal load.

Focus On Energy Efficiency First For B2B Buyers Business operating expenses are important to B2B buyers especially in the telecom, automation, and power distribution industries because their infrastructure is power-intensive. EC fan technology offers power-saving opportunities which translates into measurable business value and a strong market differentiator. It can also reduce the total cost of ownership (TCO).

EC fans are temperature-responsive and adjust their speed dynamically, unlike AC fans, which operate at a constant maximum output. EC fans prevent energy waste while also protecting against overheating and unnecessary wear on components. Moreover, the integration of filter systems with fans ensures that the fan works actively to maintain clean airflow, enhancing long-term efficiency and reducing thermal spikes from obstructed airflow.

Many companies have reported switching to EC-based cooling systems have reduced energy consumption by up to 30%. This helps achieve internal sustainability goals, while also complying with external regulatory requirements. For this reason, EC fans are a prudent investment.

Elevated System Management and Connectivity

The scope of industrial cooling has changed from mere air distribution to advanced multifunctional systems. EC fans are designed for smart buildings and can connect with BMS, PLCs, or custom tracking systems. Their integrated electronics make possible:

Speed adjustment through analog inputs or digital commands

Fault diagnosis and alarm signaling

Maintenance forecasting like RPM and motor temperature monitoring

Adaptive response to changing environments

To provide an example, an EC fan will increase its speed if a panel’s internal temperature surpasses a set value. It then throttles back to a quieter state once excess heat is eliminated. Together with a filter fan, the system is self-cleaning and self-operating.

This degree of automation is ideal for modern industries because systems designed for monitoring and automated intelligent response are critical to uninterrupted operation and reliability.

Quieter Operation and Smaller Size

In many industrial applications, space is limited and every inch counts. Traditional AC fans often require extra separation because of heat and noise. In comparison to AC fans, EC fans are quieter and more efficient. Therefore, they are more suitable for:

Electrical cabinets

Compact server racks

Factory automation units

Environmental test chambers

Moreover, installation of the fan with filter reduces the spent active particle accumulation, which increases the proximity to critical heat sensitive components. Lower noise emissions can also assist in control room operations where HVAC noise levels affect comfort and communication.

Reduced Maintenance and Reliability Improvements

One of the most overlooked advantages with EC fan systems is reliability. Brushless motors increase reliability by reducing friction and improving lifespan and mean time between failures (MTBF). Adding a fan with a filter increases reliability even more. Fans with filters capture small debris, dust, and metal particles that could damage moving parts and airflow pathways before the shafts rotate.

Additional benefits of maintenance are:

Reducing the number of replacements required for fans

Decreased manual cleaning needed

Predictive electronics built-in systems signal failures

Dependable cooling during severe environmental conditions

Industrial clients in remote or hard-to-reach areas such as wind turbine enclosures and base stations greatly benefit from these low-maintenance units.

Sustainable Manufacturing and Compliance

For B2B clients, sustainability extends beyond a buzzword with energy regulations and compliance limits. EC fans aid green-design initiatives due to their lower power consumption and use of materials, thus aligning with efforts on sustainability.

From an OEM’s perspective, installing an EC fan and a filter-equipped fan not only meets current standards like ErP or RoHS, but also shields product lines from future legislative shifts. This approach makes the EC-based cooling systems not just a technical upgrade, but also a strategic enhancement to the product’s long-term sustainability.

Final remarks

In the EC fans’ upgrade, we witnessed a jump in the development of industrial cooling. These components are intelligent and dependable, which allows manufacturers to enhance operational efficiency and streamline maintenance while meeting energy targets.

An integrated solution consisting of a filter and an EC fan, as well as a fan, provides comprehensive cooling for numerous sectors, such as machine cabinets and data centers. For business clients focused on improving their thermal management systems, EC fans prove to be an essential component of efficient thermal management systems.

As a person engaged in system integration, panel building, or industrial design, you should consider taking advantage of the EC fan technology. It is state of the art, offers scalability, and is perfect for powering next-generation industrial cooling systems.