Are you curious about what’s changing in metal casting today?

New trends are making the process faster, cleaner, and more efficient. These changes are helping many industries, from car making to building machines.

As technology improves, so do the tools and methods used in casting. Companies now want better results with less waste. They also want stronger and lighter metal parts.

In the sections below, you’ll learn about six key trends shaping the future of metal casting and why they matter for today’s industrial work.

1. 3D Printing in Casting

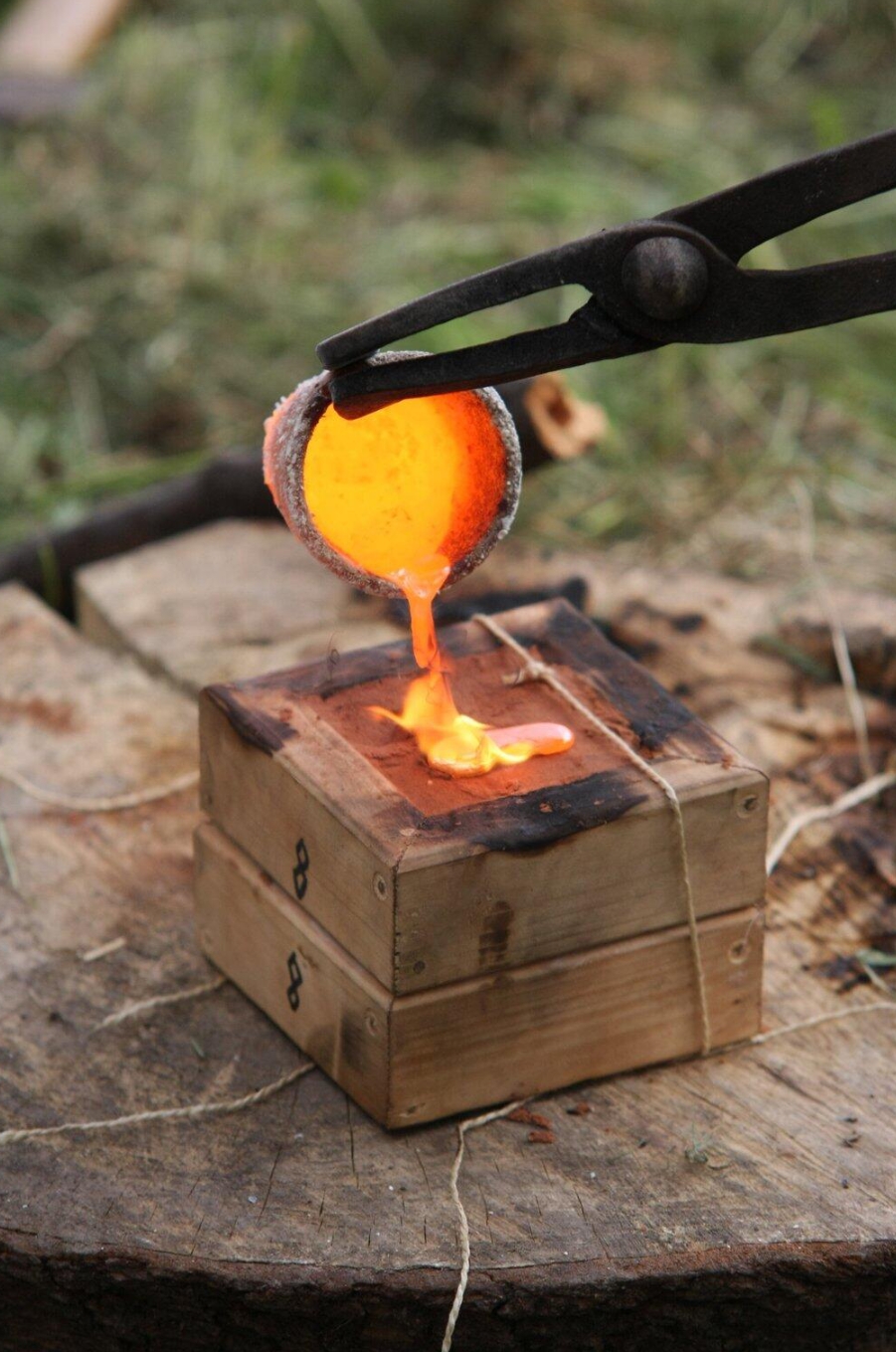

Many casting companies now use 3D printing to make patterns and molds. This helps create detailed parts quickly and with less waste. A foundry for investment casting can now use printed wax or plastic models instead of older tools. These models are more accurate and help reduce mistakes during the process.

3D printing also makes it easier to try new designs before full production. It saves time because there’s no need to build metal tools for testing. This helps both small and large projects stay on schedule and within budget.

2. Eco-Friendly Casting Methods

Modern casting methods are focusing more on the environment. New systems use less energy and cut down on harmful gases. Factories are finding better ways to melt metals without polluting the air. Some also recycle old metals to reduce waste.

Cleaner fuels and smarter tools help protect workers and nearby communities. These changes are not only good for nature but also save money. Many industries now choose eco-friendly casting to meet new safety and clean-air rules.

3. Advanced Automation Tools

Automation is changing how metal casting is done. Machines and robots now handle tasks such as pouring, lifting, and cooling. These tools work faster than people and lower the chance of mistakes. They also help keep workers safe from heat and heavy loads.

Smart systems can track every step of the casting process. This helps keep quality high and limits delays. Many factories now use these tools to improve speed and stay ahead of the competition.

4. Use of Lightweight Alloys

Many industries need strong parts that are not too heavy. That’s why casting companies are using new lightweight alloys. These metals help in making cars, planes, and machines run better.

Lightweight alloys are strong and last a long time. They work well in hot or cold conditions. Many foundries now choose these metals to meet modern needs without losing strength.

5. Real-Time Quality Checks

New tools now check metal parts while they are being made. These checks help find cracks, air bubbles, or weak spots early. Fixing problems right away saves time and materials.

Cameras and sensors watch the process as it happens. They send alerts when something goes wrong. This helps the factory take action fast and keep each part at a high quality.

6. Digital Simulation Software

Casting experts now use digital software to test their designs. The program shows how metal will flow and cool inside a mold. This helps spot problems before making the part. It also saves money by lowering the number of failed tries.

Many foundries use this software to speed up their work. It helps them choose the best mold shape and pouring speed. These tools improve accuracy and cut down on delays.

Looking Ahead in Metal Casting

Metal casting is changing fast with the help of new tools and ideas. These changes make work easier, faster, and cleaner.

As more industries use better methods, the results continue to improve. Stronger parts and smarter systems will lead the way forward.

Please take a look at our blog for more educational articles.